Since the moment of the quarantine introduction, National University “Yuri Kondratyuk Poltava Polytechnic” has switched to the distanced (online) education and work. Despite the special working conditions, the academic personnel continues successfully performing research in addition to ensuring quality educational process. In response to the needs of society, some university laboratories are now used for public health protection, just like at European universities.

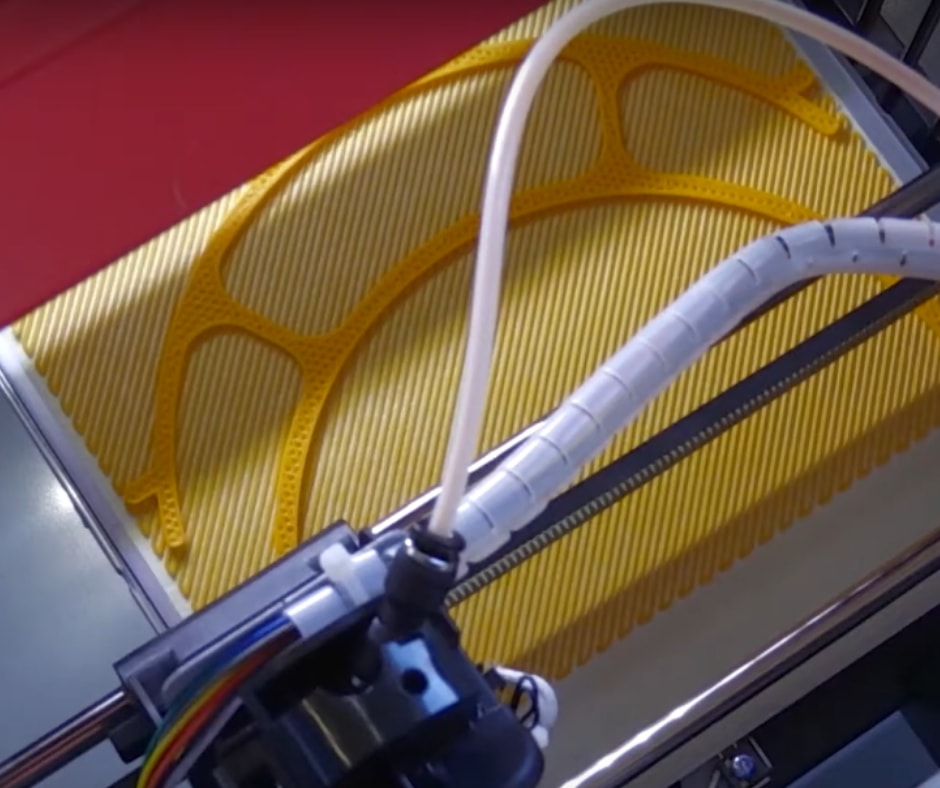

“The scientists of National University “Yuri Kondratyuk Poltava Polytechnic” developed their own enhanced design of the model and performed test printing of faceshields using 3D technologies. They are supplied first of all to our employees, supporting personnel, that maintain the campuses of university. I am thankful to the Department of Architecture and Town Planning, its Assistant Professor Andrii Koniuk and Associate Professor Kostiantyn Trehubov for the creative initiatives they demonstrated! University supported the realization of the idea and provided necessary production material. Faceshields protect not only eyes, but also face skin left open while wearing simple personal masks. We use our resources as effectively as possible to make our contribution to health service,” said Rector of National University “Yuri Kondratyuk Poltava Polytechnic”, Professor Volodymyr Onyshchenko.

The 3D model of faceshield plastic holder was created by Kostiantyn Trehubov, Associate Professor of the Department of Architecture and Town Planning at Educational and Scientific Institute of Architecture and Construction. His model is designed with better regard to the human anatomical features to hold the faceshield.

“The printer (XYZ da Vinci 1.0 Pro), which prints with using thermoplastic fibre - filament, heats up to 250 degrees and prints layer after layer. The faceshield is multilayered and can be disinfected,” explained the Deputy Head of the Department of Architecture and Town Planning, Assistant Professor Andrii Koniuk.

Production of one faceshield takes up to two hours. Rector Volodymyr Onyshchenko announced that as soon as the first complete part of faceshields is ready, the scientists will give the protection equipment to the medical personnel of Poltava Regional Infectious Disease Hospital.

Watch the video news at the YouTube channel of Poltava Polytechnic: https://www.youtube.com/watch?v=aRtO8EVdTIw

The Media Center of

National University “Yuri Kondratyuk Poltava Polytechnic”